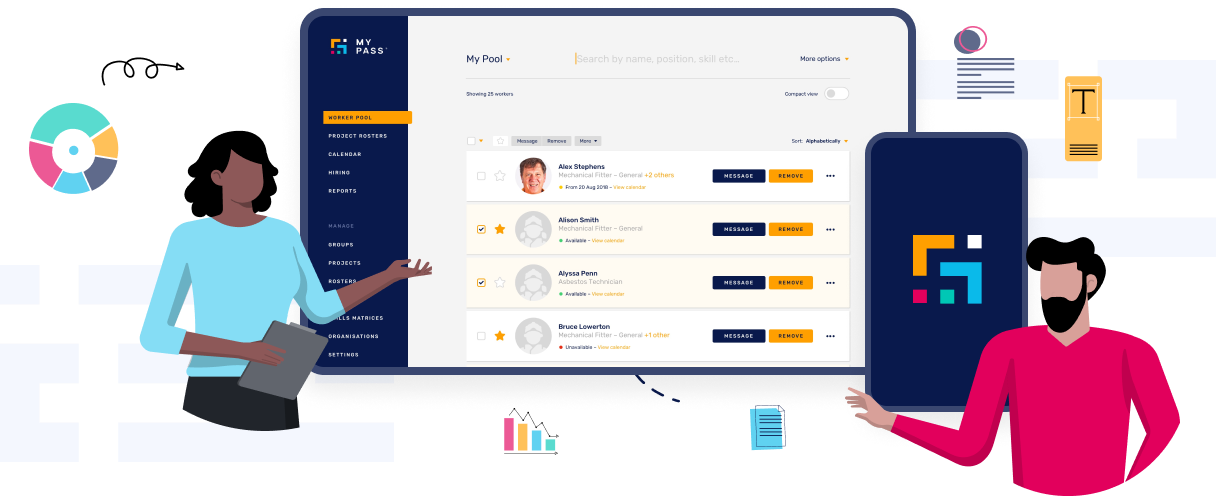

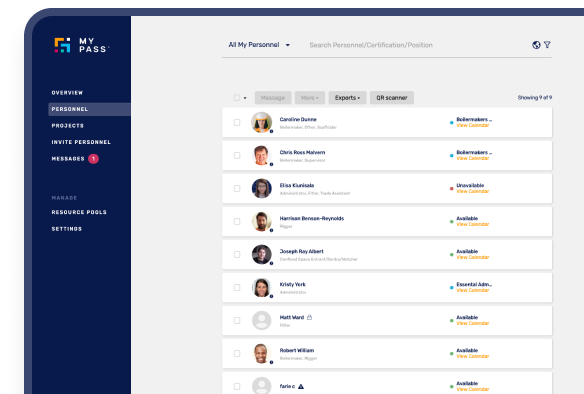

MyPass® Helps you

Ensure Compliance

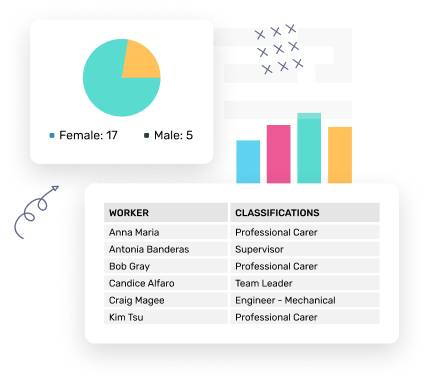

Gain hand-on-heart assurance that the right people with the right skills are performing their allocated tasks. Monitor real-time dashboards, check percentage compliance, and much more.

"We are using MyPass® to manage our specialist and multi-skilled trades... getting the confidence that the employees’ training, qualifications and compliance documents are up to date – easily, effectively and quickly."

Broadspectrum LinkedIn Post

- Efficiently pre-qualify and mobilise contractors

- Real-time visibility of certificates and licences

- Copy

- Copy